Over the last 15+ years I’ve worked with many medical device companies as CEO of Vonco Products. In that span of time, I’ve heard the following issues raised many times by clients: medical devices are highly regulated, the market is extremely competitive, manufacturing expertise is difficult to find – and perhaps most important – controlling costs while maintaining stringent quality standards is paramount.

While I agree with all those concerns, the focus of this article will be on the critical strategies necessary to ensure quality while also keeping an eye on maintaining costs.

According to McKinsey, enhancing quality isn’t just about compliance or patient safety, it also has a direct impact on reducing costs. They estimate that the total direct cost of quality in the medical device industry ranges from 6.8% to 9.4% of industry sales, equating to $26 billion to $36 billion annually. By adopting leading quality practices, companies could recover $6 billion to $11 billion per year, representing about 1.5% to 3.0% of sales.

“Improving quality can bring costs down significantly. New analysis and industry examples suggest a way forward for device makers.”

This evidence supports the notion that strategic investments in quality can lead to substantial cost savings. To ensure quality while also maintaining costs, consider the following:

Lean Manufacturing: Eliminating Waste for Efficiency

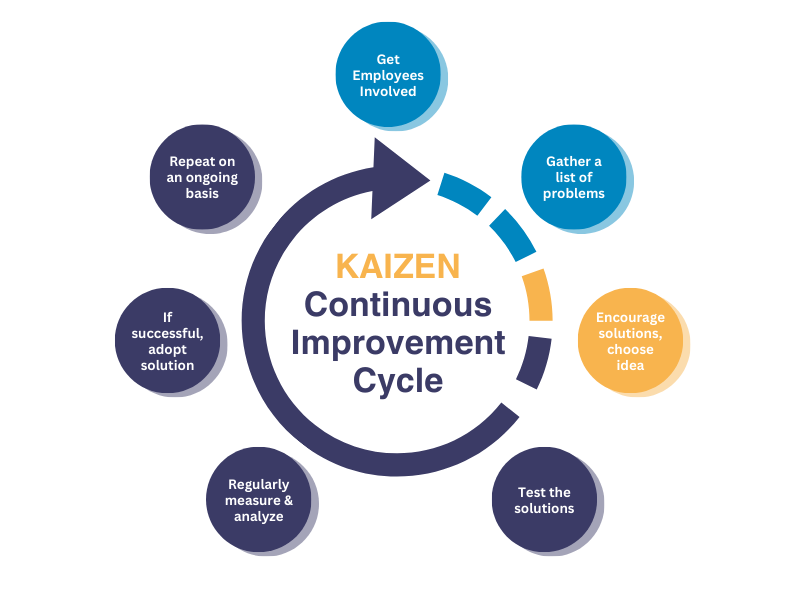

Lean manufacturing principles focus on minimizing waste without sacrificing productivity. By implementing just-in-time (JIT) inventory systems, manufacturers can reduce holding costs and improve cash flow. Continuous improvement (Kaizen) and process standardization further enhance efficiency, leading to cost savings and improved product quality.

- Just-in-Time (JIT) Inventory: Reduces excess inventory and storage costs by receiving materials only as needed in the production process

- Kaizen (Continuous Improvement): Encourages ongoing, incremental improvements in workflows, promoting team engagement and operational efficiency

- Standardized Workflows: Streamlines processes to reduce variability, improve consistency, and simplify training across teams

- Waste Elimination: Targets non-value-adding activities such as overproduction, waiting time, and defects to enhance overall productivity

Process Optimization: Enhancing Production Workflows

Optimizing production processes can lead to significant cost reductions. Investing in automation and improved tooling can decrease assembly time and reduce production scrap. For instance, effective automation and tooling improvements have the potential to save more than 50% of manufacturing costs.

- Automation Integration: Increases throughput and consistency while reducing labor costs and human error

- Advanced Tooling: Enhances precision and repeatability, minimizing defects and rework

- Cycle Time Reduction: Speeds up production by streamlining repetitive tasks and reducing machine downtime

- Scrap and Waste Minimization: Lowers material loss by improving accuracy and efficiency in production steps

Material Cost Management: Strategic Sourcing and Procurement

Raw materials and components constitute a substantial portion of manufacturing expenses, accounting for 40-60% of total costs. To manage these costs:

- Establish strong relationships with suppliers to negotiate better pricing and ensure reliable delivery

- Implement just-in-time inventory management to minimize storage costs and reduce waste

- Explore alternative materials that offer similar performance at reduced costs

By adopting these strategies, medical device manufacturers can mitigate the impact of material cost fluctuations and supply chain disruptions.

Balancing Cost with Quality: Ensuring Compliance and Excellence

Maintaining high-quality standards is non-negotiable in medical device manufacturing. Quality control and compliance costs can account for up to 5-10% of the total operational budget. To balance cost with quality:

- Invest in automated quality systems to reduce labor costs and improve accuracy

- Implement efficient inventory management to minimize wastage and storage costs

- Conduct regular supplier audits to ensure consistent material quality and reduce variability

These measures not only ensure compliance with regulatory standards but also contribute to overall cost savings.

Conclusion

Effective cost management in medical device manufacturing requires a multifaceted approach that includes lean manufacturing, process optimization, strategic sourcing, and a steadfast commitment to quality. By partnering with a contract manufacturer to help you implement these strategies, OEMs can enhance efficiency, reduce expenses, and maintain the high-quality standards essential for success in the medical device industry.