In today’s fast-paced and competitive landscape, innovation and efficiency are paramount. At Vonco, Design for Manufacturability (DFM) is not just a methodology – it’s the cornerstone of how we deliver tailored, high-quality solutions optimized for production efficiency and market readiness.

Whether it’s medical device packaging, flexible film applications, or innovative IV bags, our approach to DFM is built on creativity, precision, and customer-centricity.

What Is DFM at Vonco?

Design for Manufacturability is an engineering practice that considers how a product will be manufactured alongside its functionality and appearance. At Vonco, we leverage DFM to:

- Streamline production processes

- Reduce costs

- Improve product quality

- Accelerate time-to-market

How Vonco Implements DFM

The best approach to Design for Manufacturability incorporates a strategy tailored to meet the unique needs of clients and ensures that solutions are both practical and innovative. As you evaluate contract manufacturing partners, consider the following areas of DFM expertise:

1. Tailored Solutions

From complex high risk medical devices to consumer packaging, we ensure products meet both functional and ergonomic requirements. Our initial scoping calls and exploratory meetings prioritize usability, material selection, and user feedback, ensuring alignment with client goals. This risk based and user-focused approach enables us to design innovative solutions, including customizable medical packaging and flexible film applications.

2. Advanced Materials

Our deep expertise in flexible films and substrates drives our ability to solve complex challenges. Whether designing barrier structures to protect sterile devices, engineering materials for seamless sealing, or addressing dynamic product requirements, our knowledge ensures solutions tailored to each application. By blending innovative material science with precise execution, we elevate every project from concept to commercial readiness.

3. Deep Collaboration

DFM is the most effective when integrated early in the design process. At Vonco, we engage clients at the conceptual stage to proactively identify potential challenges. This approach reduces development costs, minimizes redesign delays, and ensures a seamless transition from design to production.

4. Effective Partnerships

Through interactive meetings and open-order reviews with stakeholders, we foster a transparent and collaborative environment. Feedback loops, such as usability studies and mockup reviews from our rapid prototyping spark sessions, are integral to refining our designs and exceeding expectations.

5. State-of-the-Art Facilities

Our facilities are designed to accommodate diverse project requirements. With inline systems for lamination and manual turntable setups for intricate RF welding, we ensure precision and quality. The flexibility of our operations allows us to seamlessly switch between product lines and respond swiftly to evolving client needs.

6. Problem-Solving

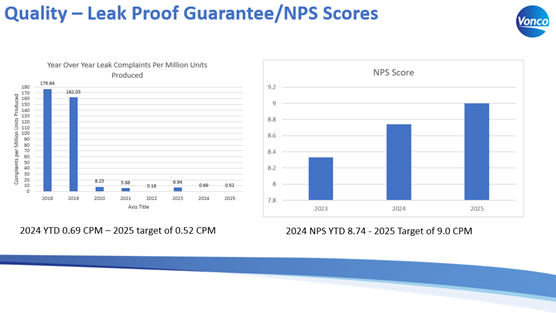

Leaks in flexible welded plastic containers or defects in sterile barrier medical packaging are unfortunately common and can result in costly recalls. At Vonco, we mitigate these risks by developing leak-proof products backed by our Liquid Lock Guarantee.

During the product and process design phase, we prioritize establishing robust process controls and innovative designs to ensure every product manufactured achieves perfect seals. This is accomplished through the strategic design of tooling and the implementation of poka-yoke processes that prevent costly defects and guarantee consistent, high-quality results.

Inconsistent spout and cap compatibility or static build-up in controlled environments can present unique challenges. Through iterative testing and process refinement, we provide dependable solutions tailored to our client’s needs. Our deep expertise in material selection is pivotal in addressing critical challenges like barrier integrity, sterilization compatibility, and leakage prevention. By meticulously analyzing material properties and optimizing their compatibility with advanced sealing techniques, we consistently deliver high-quality products that exceed stringent industry standards.

7. Roadmap to Commercialization

Our structured approach to commercialization integrates key stages to accelerate time-to-market while maintaining quality and compliance:

- Concept Validation: Iterative rapid prototyping through our spark sessions helps spark concept development projects towards development by providing customers with physical samples and client collaboration refine concepts into actionable designs.

- Pilot Production: Small-scale batches ensure seamless scaling and identify optimization opportunities.

- Regulatory Support: Expertise in ISO standards and FDA compliance streamlines approval processes.

- Full-Scale Production: High-volume production with a focus on efficiency and consistency.

- Market Launch and Beyond: Post-launch services include packaging updates and ongoing technical assistance.

Why Choose Vonco for DFM?

We bring decades of experience and a collaborative mindset to every project. Our DFM expertise ensures that your product is optimized for manufacturing without compromising on quality or innovation. Our holistic approach, incorporating Design for Manufacturing and Assembly (DFMA) principles, simplifies both manufacturing and assembly processes, further reducing costs and accelerating delivery timelines.

Whether launching a new product or refining an existing one, our DFM expertise turns visions into reality. Contact us today to discover how our solutions can drive your success through innovation, precision, and efficiency.